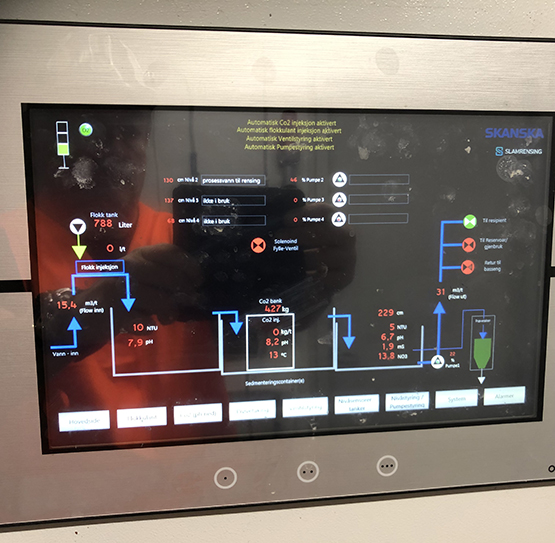

“Hydrochloric and sulfuric acid is harder to dose accurately and makes it difficult to fulfil the emission demands. 96 per cent sulfuric acid and 40 % hydrochloric acid is risky, both regarding transportation and handling on site. The use of carbon dioxide (CO2) is safer in the workplace, in addition to being easier to dose within the right measurement levels. With CO2 it is impossible to overdose», says Lars Engen, leader of water treatment in Skanska Norway.

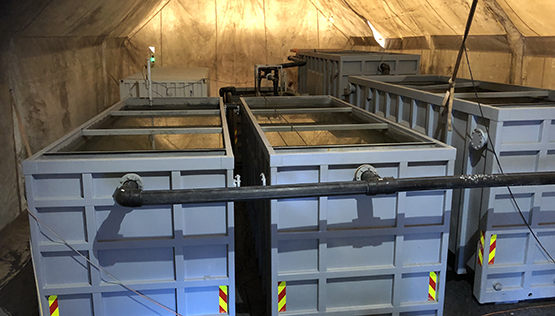

Skanska met the strict environmental demands from Oslo Municipality and the drilling of the new water tunnel commenced in the beginning of 2023. The construction sites are fossil free and the construction machines, conveyor belts and TBM - Tunnel Boring Machines are run by electrical power. The project is planned to be finalized in 2028.

«Linde provides tanks with liquid carbon dioxide and evaporator, to make sure the CO2 is dissolved in the water and the pH-levels fulfil the environmental requirements before the water is released into surrounding nature. Linde makes sure that the tanks always are filled up with CO2 using automatic remote monitoring”, says Kjetil Veidel, application engineer in Linde.

Text: Ingalill Sandal

Photo: Skanska and Shutterstock